An engine’s oil pump is crucial in maintaining lubrication and preventing excessive wear on internal components. However, installing a new oil pump or after an engine rebuild, it must be primed before starting the engine. Priming an engine oil pump ensures proper oil circulation, preventing dry starts and engine failure.

In this post guide, we’ll explain what an oil pump does, why priming is important, and a step-by-step process to do it correctly.

Priming Engine Oil Pump

An engine oil pump is a mechanical device responsible for circulating engine oil throughout the internal components. It ensures that critical parts, such as bearings and pistons, receive adequate lubrication.

Types of Oil Pumps

- Gear Oil Pump – Uses rotating gears to push oil through the engine.

- Rotor Oil Pump – This pump uses a rotor and an outer gear to move oil efficiently.

- Electric Oil Pump – Found in modern vehicles, it operates independently of the engine’s rotation.

Best Priming Engine Oil Pump

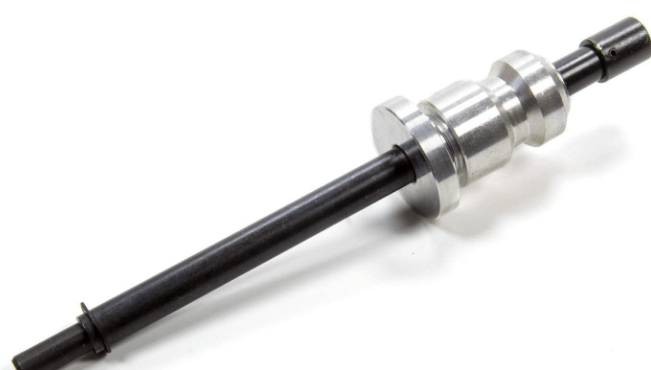

1. Proform 66896 Oil Pump Primer

Suitable for V8 and V6 engines, this primer tool features a bushing for added stability during operation, ensuring thorough lubrication before engine startup.

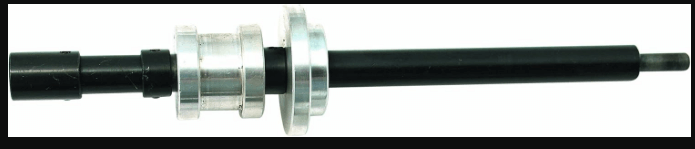

2. CTA Tools 2101 Oil Pump Primer

- Primes the Lubricating System of New and Rebuilt Engines

- Sends Oil to the Internal Moving Parts Before the First Start

- Used with a 3/8-Inch or 1/2-Inch Reversible Drill

- Heavy-duty construction Allows for Strength and Durability

3. DPTOOL Oil Pump Primer Tool

This oil pump primer lets you spin the oil pump with a drill motor bringing up the oil pressure and moving the oil to the top of the engine before starting the engine, preventing unnecessary wear or damage to rotating and valve train components.

Why Priming an Oil Pump is Necessary

Priming an oil pump is not optional—it’s a crucial step to ensure the longevity of your engine. Here’s why:

- Prevents Dry Starts – Without oil, internal engine parts experience high friction and wear.

- Ensures Immediate Lubrication – Oil reaches key components as soon as the engine starts.

- Reduces Risk of Engine Damage – Running an engine with an unprimed pump can cause irreversible damage.

Skipping priming could lead to catastrophic engine failure, making this step a must.

Related Clearview Filtration Engine Oil Filter(Comprehensive Guide)

When Should You Prime an Oil Pump?

There are specific situations where priming is required:

- After Installing a New Oil Pump – A dry pump needs oil circulation before starting.

- Following an Engine Rebuild – Oil galleries may be empty, requiring priming.

- After Long-Term Storage – Oil settles and drains over time, leading to dry start risks.

How to Prime an Engine Oil Pump

Step 1: Gather the Required Tools

Before you start, make sure you have the following:

- Oil filter wrench

- Fresh engine oil

- Priming tool (or a drill with a priming shaft)

- Ratchet and socket set

- Oil catch pan

Step 2: Fill the Oil Filter with Fresh Oil

- Before installing the oil filter, pour fresh oil into it.

- Let the oil soak into the filter media to prevent dry starts.

Step 3: Install the Oil Pump Properly

- Secure the oil pump in place according to the manufacturer’s instructions.

- Ensure all bolts are tightened correctly.

Related How Tight Does an Oil Filter Need To Be(Avoid This Mistake)

Step 4: Use a Priming Tool or Drill

- Insert a priming tool (or a modified drill with a priming shaft) into the distributor hole.

- Rotate the tool counterclockwise (for most engines) to circulate oil.

- Continue for 30–60 seconds until oil pressure builds up.

Step 5: Check for Oil Flow

- Look for oil reaching rocker arms and pushrods.

- If oil doesn’t flow, continue priming.

Step 6: Reassemble and Start the Engine

- Remove the priming tool.

- Reinstall the distributor (if applicable).

- Start the engine and check for proper oil pressure.

Related Car Engine Oil Color Chart(Color That Signals Immediate Danger)

Precautions to Take Before Priming

- Ensure the engine is off and cool before starting.

- Wear protective gloves to avoid oil spills.

- Verify oil level before priming.

- Do not over-tighten the oil pump bolts.

Common Mistakes to Avoid

- Skipping Priming Altogether – Leads to engine damage.

- Using the Wrong Oil – Always use the recommended oil grade.

- Not Checking Oil Flow – Ensuring proper oil circulation is crucial.

- Running the Engine Without Pressure – If no oil pressure is detected, shut down immediately.

Related Engine Oil Consumption Chart(For All Engine Types)

How Long Does it Take to Prime an Oil Pump?

The priming process typically takes 30 seconds to 1 minute. However, depending on engine type and oil viscosity, it may take up to 2 minutes.

Troubleshooting Issues After Priming

If oil pressure does not build up after priming:

✔ Recheck the oil level – Low oil levels cause pressure loss.

✔ Inspect for air leaks – Air pockets in the oil system can prevent circulation.

✔ Confirm correct tool usage – Ensure the priming tool is properly engaged.

Related Zinc Additive Engine Oil(Benefits & Hidden Formula)

Benefits of Proper Oil Pump Priming

- Extends engine life

- Prevents unnecessary repairs

- Reduces wear and tear

- Ensures smooth startup

FAQs

Can I prime an oil pump without a priming tool?

Yes! You can use a drill with a priming shaft as an alternative.

Do all engines require oil pump priming?

Not all, but newly installed oil pumps, rebuilt engines, and long-stored engines must be primed.

What happens if I don’t prime the oil pump?

A dry start can cause severe engine damage, leading to costly repairs.

How do I know if priming was successful?

Check for oil flow in the rocker’s arms or verify oil pressure on the gauge.

Can I use old oil for priming?

No! Always use fresh, clean engine oil for priming.

Related Diesel Engine Oil Additives(Benefits & Top Oil Additives)

Final word

Priming an engine oil pump is an essential step in maintaining engine health. Whether installing a new pump or reviving a stored engine, this process ensures proper lubrication and prevents damage.