Honing oil acts as a lubricant and coolant, preventing metal particles from clogging the abrasive stones and minimizing friction and heat during the honing process. In this guide, we’ll explore the importance of honing oil, what makes a good one, and highlight five of the best engine cylinder honing oils available on the market.

Engine Cylinder Honing Oil

1. Flex Hone Honing Oil

Flex-Hone, a petroleum-based honing oil designed for high-performance cylinder honing. It’s widely used in professional automotive machine shops and delivers consistent results.

Features:

- Low viscosity for fast cutting action

- Excellent cooling and flushing properties

- Ideal for use with aluminum oxide and silicon carbide stones

- Reduces stone loading and metal glazing

- Trusted by engine builders worldwide

2. Goodson HO-10 Honing Oil

Goodson’s HO-10 honing oil is specially formulated for use in cylinder honing machines. It’s known for its clean-running characteristics and ability to extend abrasive life.

Features:

- Petroleum-based with special additives for smooth honing

- Designed to resist oxidation and sludge formation

- Effective in suspending metal particles

- Compatible with most honing stones

- Preferred in engine rebuilding environments

3. Lucas Oil 10070 Engine Break-In and Honing Oil

While primarily marketed as a break-in oil, Lucas Oil 10070 also works well as a honing fluid thanks to its high lubricity and anti-wear additives. It’s ideal for those combining honing and break-in preparation.

Features:

- Designed to reduce metal-to-metal wear during engine prep

- Excellent protection for cylinder walls during honing

- Contains zinc and phosphorus additives

- Useful in both honing and engine assembly

- Helps with piston ring seating and oil retention

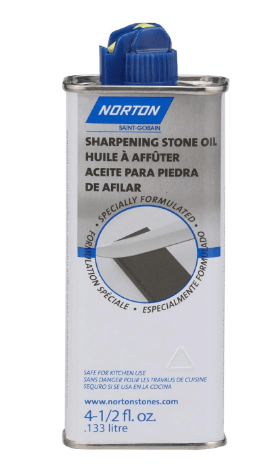

4. Norton Abrasives Cylinder Honing Oil

Norton is a reputable name in the abrasive and tooling industry. Their honing oil is made for use with honing stones and works effectively for hand or machine honing of engine cylinders.

Features:

- Light mineral-based oil for superior flushing

- Prevents stone glazing and material loading

- Offers a consistent surface finish with minimal effort

- Clean, non-gumming formula

- Suitable for use with various honing tools

5. Vogel Honing Oil HV-125

Vogel HV-125 is a high-performance honing oil suitable for the precision honing of engine blocks. It is engineered to deliver clean cuts, extend abrasive life, and ensure a fine surface finish.

Features:

- Medium viscosity with excellent lubricity

- Contains anti-wear and anti-foaming agents

- Resists varnish and deposit buildup

- Reduces drag and heat during honing

- Compatible with various metal types

Related Low Ash Engine Oil(Explained + Top 3 Best Picks)

Key Features to Look for in Honing Oil

When choosing a honing oil for engine cylinders, keep these important factors in mind:

- Lubrication Quality: Ensures smooth honing without excessive friction.

- Cooling Properties: Prevents heat buildup that can cause warping or micro-scoring.

- Metal Debris Suspension: Helps keep abrasive particles away from the honing surface.

- Compatibility: Must be suitable for the material being honed (cast iron, aluminum, steel).

- Non-gumming Formula: Leaves no sticky residues that can interfere with engine assembly.

Related Marvel Mystery Oil Engine Flush(Read This Before You Buy)

Why Use Honing Oil?

Honing oil is a specialized lubricant designed to improve the performance and longevity of honing stones and help produce a consistent finish. The oil flushes out metal debris from the honing surface, keeps temperatures low, and reduces wear on both the stone and the metal being honed.

Using the wrong type of oil, or worse, no oil at all, can result in poor surface finish, glazed stones, excessive wear, and even damage to the engine cylinder walls. That’s why experienced engine builders always insist on using high-quality honing oil for precision cylinder work.

Related Is Engine Flush Before Oil Change Worth It(Dos & Dont)

How to Use Honing Oil Properly

Using honing oil is simple, but it must be done right to maximize its benefits:

- Clean the Cylinder: Before applying oil, remove any dirt or debris from the cylinder bore.

- Apply Generously: Coat both the cylinder surface and honing stones with oil.

- Maintain Flow: During honing, continue applying oil or ensure your machine has a constant oil feed.

- Flush After Honing: Clean the cylinder thoroughly to remove any residual oil and metal particles before engine assembly.

Related Semi Synthetic Engine Oil vs Fully Synthetic(Which Should You Choose)

FAQs

What oil to use when honing a cylinder?

When honing a cylinder, use a dedicated honing oil such as Sunnen MB-30, Goodson HO-10, or Vogel HV-125. These oils are specifically formulated to reduce friction, carry away debris, and provide cooling during the honing process. Avoid using general-purpose lubricants or motor oils, as they may not offer the proper viscosity or metal suspension properties needed for effective honing.

What is honing oil used for?

Honing oil serves as a lubricant and coolant during the honing process. It reduces friction between the honing stones and the cylinder wall, flushes out metal particles, prevents stone glazing, and helps achieve a smooth, crosshatched surface finish. This is essential for proper piston ring seating and oil retention in engine cylinders.

Related Engine Oil With Most Zinc(Top 5 Best 2025)

What can I use as a substitute for honing oil?

While it’s best to use purpose-made honing oil, light mineral oil or a mixture of mineral oil and kerosene can work as temporary substitutes. Automatic transmission fluid (ATF) or cutting fluids are also used in some DIY applications. However, these substitutes may not offer the same performance, cleanliness, or protection as professional honing oils.

What does honing do to a cylinder?

Honing removes minor imperfections, wear marks, and glazing from the cylinder wall while creating a fine crosshatch pattern. This pattern improves oil retention and helps piston rings seat properly, enhancing compression and minimizing oil consumption. It also restores surface geometry and prepares the cylinder for optimal engine performance.

What is a substitute for cylinder honing oil?

Substitutes for cylinder honing oil include light machine oil, mineral oil mixed with kerosene, or transmission fluid. These can provide basic lubrication and debris removal, but they may lack the additive packages and metal suspension qualities found in true honing oils. For best results, use a product specifically formulated for engine honing.

Related Diesel Engine Oil Additives(Benefits & Top Oil Additives)

Can I use water instead of honing oil?

No, water should not be used as a substitute for honing oil. Water lacks lubrication and will not protect the honing stones or the cylinder surface. Using water can lead to poor surface finish, excessive tool wear, rust formation, and potential engine damage. Always use an appropriate oil-based honing fluid for best results.

Final words

Whether you’re rebuilding an old engine or blueprinting a race engine, choosing the right honing oil is vital for achieving a proper finish, extending tool life, and ensuring engine longevity. The honing oils listed above are trusted by professionals for their consistency, lubrication quality, and cooling properties.

Always follow the honing stone and engine manufacturer’s recommendations regarding oil compatibility and application. Remember, in precision work like engine honing, the right oil can make the difference between an engine that runs smoothly and one that wears prematurely.